North of lake Molkom in Värmland, Sweden, between the two towns Karlstad and Filipstad, you will find Nords International, a fine old industrial company with a proud heritage since 1904. Nords manufactures stainless steel parts, such as threaded pipe fittings, couplings, collars and clamps, for customers all over the world.

We have been following them since February, together with business cluster IUC Stål och Verkstad, and are completely stunned by the drive, care and commitment. You just don’t want to stop hanging out with this team.

We often start out by assessing the value chain together with our customers, in order to pinpoint sustainability impacts. Everything from human rights and the risk of corruption at the supplier level to greenhouse gas emissions, safety and waste management are usually highlighted in this phase. Nords performed one as well, earlier this spring.

The assessment often provides a great deal of aha-moments

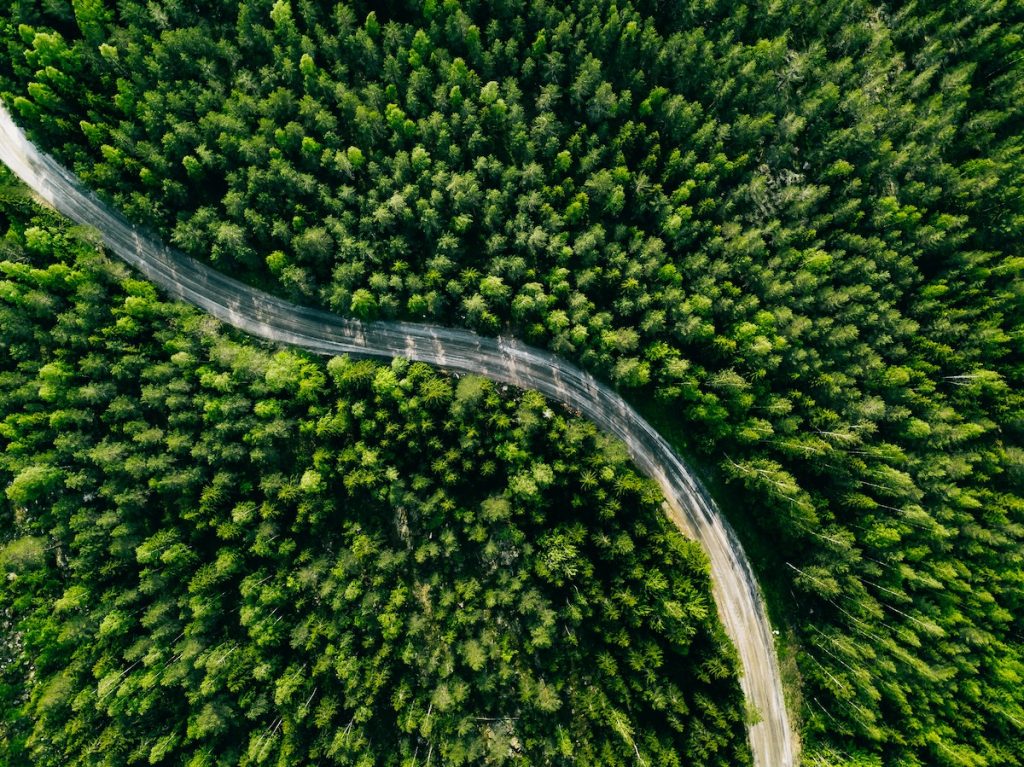

When Sustainability Manager Per-Åke Ragnarsson started to map carbon dioxide emissions in the value chain, he was a bit surprised. It turned out that the emissions from staff commuting to and from work are many times higher than the company’s own emissions *. It is just over 30 kilometers from Karlstad to Molkom, and the same distance from Filipstad, so there are many employees who drive quite a few miles by car every day. Emissions alone is a problem, but it’s also expensive for the employees. But the bus rarely operates the countryside and most companies would probably have settled there: if you work in Molkom, you drive.

Not Nords, however. Per-Åke immediately started counting. Seventy miles a day for 205 days adds up to SEK 28,700 per year if you count SEK 20 per mile. An annual pass on the bus costs SEK 13,390. If Nord’s employees could take the bus instead of driving, each employee would save SEK 15,310 per year. Even though some ride together, they would still save money by riding a bus.

But the bus schedule doesn’t match the working hours? “No, but who says you can’s change that,” says Per-Åke. “If we don’t ask, we’ll get no change. Maybe we can even discuss the price of the pass? Why not ask? There are more companies in Molkom – maybe we can get special work buses?”

Nords has just finalized their materiality analysis

On Thursday, the management team completed its very first materiality analysis. It shows the most important areas for Nords to focus on in the coming years, both from a strategic business perspective and from the stakeholders’ point of view. It is an impressive job behind the result and now they have a fact-based foundation to continue working from.

Great job, Nords. We’re proud of you and proud of working together with you!

*Greenhouse Gas Protocol, scope 1 (emissions from own operations, own and leased cars) and scope 2 (purchased electricity, heat, cooling etc.). Scope 3 is the rest – up- and downstream emissions throughout the value chain.